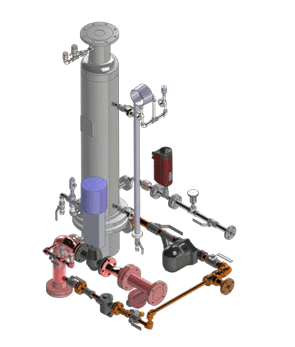

The clean steam generator is used to avoid chemicals normally used in steam water treatment, in steam injection processes such as humidification and sterilization. It is a shell and tube steam–to–steam heat exchanger designed to use higher steam pressure from the steam boiler and generate lower clean steam pressure for the process. The clean steam comes from the feed clean water. Meaning if you use softener water treatment before feeding the clean steam generator, you will generate soft clean steam, if you use reverse osmosis water to feed the steam to steam heat exchanger, you will generate RO clean steam.

The operation of the clean steam generator is similar to that of a steam boiler. Instead of being gas-fired, it is steam-fired. Therefor, we include a surface blowdown controller to keep the conductivity low inside the heat exchanger. And the blowdown rate is directly related to your water quality. We strongly recommend the use of Reverse Osmosis feed water for the clean steam generator. Not only to reduce the surface blowdown rate but also to reduce the foam build-up on the water surface where steam separates from the water. The same phenomenon with steam boilers.

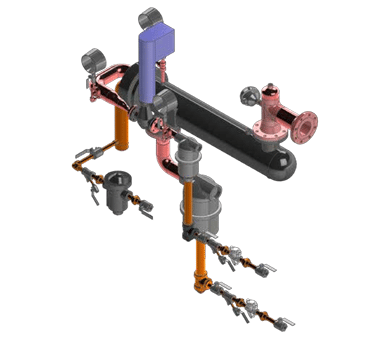

Depending of your steam pressure of operation, you might need a dedicated condensate pump station which we normally provide on all our clean steam generator skids. We typically use stainless steel 304 material and we can also provide 316L. it comes also with a water level controller and a touchscreen panel with BacNet or ModBus communication.

For sterilization processes in hospitals, pharmaceutical processes or others you should consider our steam quality controller which as nothing to do with the chemical in the steam. It has to do with the level of dryness inside the heat exchanger. The magic trick is simple. Typically, sterilizers ask for 60 psig steam pressure. By using a steam–to–steam heat exchanger, we bring the 60 spig steam on one side of the heat exchanger and on the other side we bring higher steam pressure. For example, let’s say 100 psig. We then ask the controller to keep 60 psig, but we also ask to rise the temperature of the steam of few degrees. This allows the steam quality controller to generate super-heated steam and we automatically generate 98+ steam quality.

The steam quality controller will greatly help you reduce the amount of rejection from the wet pack issue in the sterilization process.

Learn more

Please contact our team for more information on this product.