Why Sustainability Matters for Our Clients

Raven clients have signed onto Science Based Targets initiative (SBTi) or Net Zero pledges. They need practical, low-carbon heating solutions. Raven helps translate pledges into real results with proven products and strategies.

Like supplying high-efficiency boilers, electrification strategies, and heat recovery solutions engineered to cut carbon and costs without compromising reliability.

Value Propositions (3 Key Pillars)

- Decarbonization Aligned to SBTi

- Support companies with Net Zero pledges.

- Efficiency + Cost Savings

- Achieve 15–30% efficiency improvements.

- Turnkey, Right-Sized Solutions

- Scoping → Equipment → Commissioning.

Solutions We Deliver

- Electrification → Industrial-grade electric boilers, split-capacity and hybrid system strategies (Puratos case study).

- High-Efficiency Boilers → Fulton condensing platforms with PURE® controls and turndown up to 15:1.

- Heat Recovery → Economizers, SWEP brazed plate exchangers, and robust venting designs that enable safe, efficient flue gas heat reclaim.

- Hybrid Systems → Blended gas-electric or condensing + non-condensing setups for phased decarbonization.

- Advanced Controls → PID loops, BMS integration, and measurement & verification for data-driven efficiency.

- Advisory Services → Net Zero road-mapping, grants, and capex/opex modeling.

Electric Boiler for Net Zero Carbon Emission

Supporting Puratos on their path to Net Zero

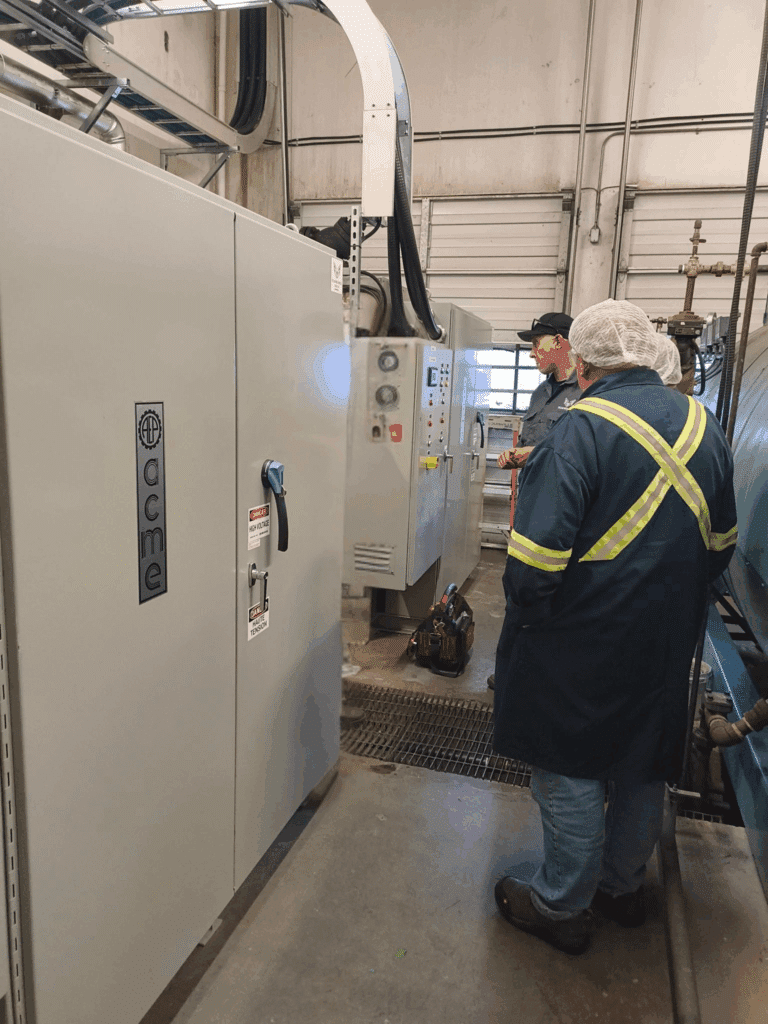

Raven Supply is proud to have partnered with Puratos to support their Net Zero emissions goals at their Fraser Valley facility.

Puratos wanted to transition away from gas-fired boilers and explored electric boiler solutions to achieve zero-emission heating. Initially, a 1,440 kW unit was considered, but this would have required the facility to hire a Class 3 Power Engineer under BC regulations, adding extra cost and complexity.

Our team at Raven worked closely with Puratos and ACME Engineering Boilers to recommend a more efficient solution:

- Splitting capacity into two 720 kW electric boilers

- Eliminating the need for a Class 3 engineer

- Delivering reliable, zero-emission performance

- Investing in operational processes to make strides towards meeting corporate sustainability targets

This project is a perfect example of how collaboration, smart design choices, and the right technology can align operational efficiency with environmental responsibility.

A big thank you to Puratos for their commitment to a better tomorrow, and to ACME Boilers for supplying the technology that made this possible.

Here’s to building a cleaner, more sustainable future, one project at a time.