Product Details

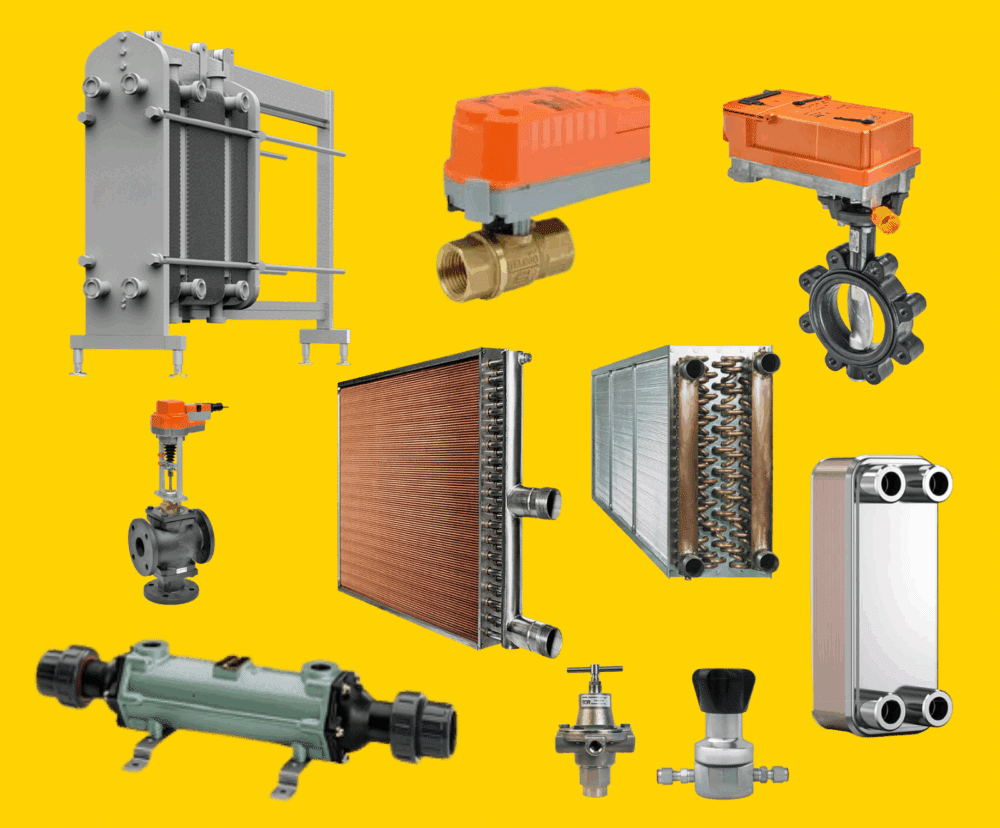

Heat Exchangers, Coils, & Regulators etc

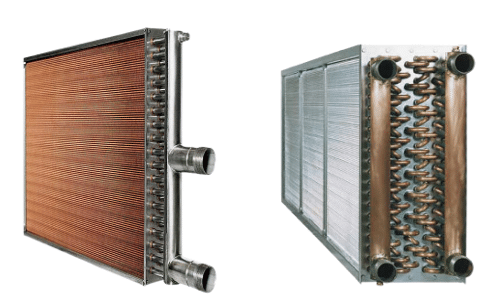

Brazed Plate Heat Exchangers

-

Single & Double Wall – Available in both single-wall for standard applications and double-wall designs for added protection against fluid cross-contamination.

-

Two-phase (Condensers) – Engineered to efficiently condense refrigerants or vapors, maximizing heat recovery in cooling and refrigeration systems.

-

Two-phase (Evaporators) – Optimized for boiling applications, providing reliable and efficient heat transfer for evaporating fluids in HVAC and industrial processes.

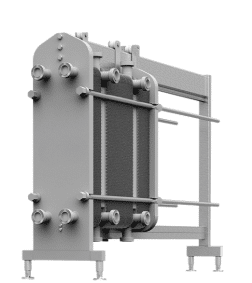

Plate and Frame

-

Gasketed Plate and Frame Family – Designed with gaskets that allow disassembly for inspection, cleaning, and maintenance, making them ideal for applications that require regular servicing.

-

Expandable, Easy Maintenance – Modular construction enables capacity increases by simply adding plates, while easy access reduces downtime and extends system life.

-

High Heat Transfer Efficiency – Corrugated plates create turbulence for superior thermal performance, delivering maximum energy savings in both heating and cooling processes.

Shell and Tube

-

Compact, High-Efficiency Design – Engineered to deliver strong thermal performance in a space-saving footprint, making them suitable for demanding industrial and commercial applications.

-

Quick-Clean Removable Tubes – Tube bundles are designed for easy access and cleaning, reducing maintenance time while extending service life and reliability.

-

316 Stainless Steel, up to 1600 kW – Built with corrosion-resistant 316 SS for durability and capable of handling high capacities up to 1600 kW.

HYDRONIC AND STEAM SAFETY RELIEF VALVES

-

ASME Section VIII Certified – Built to meet strict ASME Section VIII standards, ensuring code compliance and safe operation in both industrial and commercial applications.

-

Steam and Liquid Service – Versatile design suitable for protecting systems operating with steam, hot water, or other liquids, providing reliable overpressure protection across applications.

-

Bronze and Stainless-Steel Construction – Available in durable bronze or corrosion-resistant stainless steel, with ratings up to 1,200 psi at 800°F for long service life under demanding conditions.

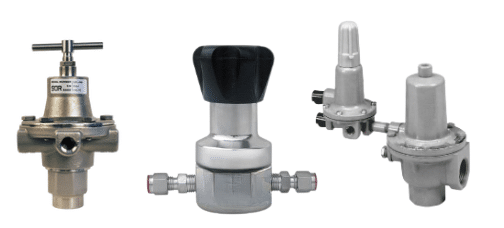

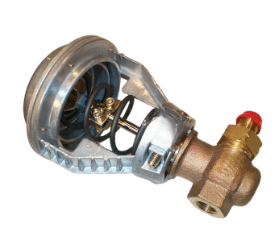

Regulators

-

Pressure Reducing Regulators – Maintain steady downstream pressure for steam, air, and gas systems, improving efficiency and protecting equipment.

-

Back Pressure Regulators – Automatically relieve excess upstream pressure to stabilize system performance and prevent overloading.

-

High-Pressure Regulators – Designed for demanding applications, handling elevated inlet pressures with reliable control and safety.

-

Pressure Indicating Control Valves – Provide both control and monitoring in one unit, ensuring precision and ease of operation.

Shutoff & Safety Valves

-

Globe, Ball, and Butterfly Valves – Versatile shutoff solutions for steam, gas, and liquid service, offering dependable sealing and flow control.

-

Sizes: ½″ to 6″ – Wide range of valve sizes accommodates everything from compact systems to large industrial pipelines.

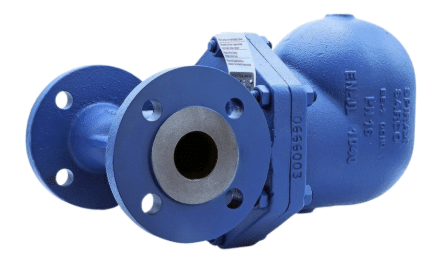

Steam Traps

-

Balanced Pressure Thermostatic Traps – Compact design ideal for light-duty steam applications, automatically adjusting to varying loads.

-

Ball Float Steam Traps – Continuous discharge models for efficient condensate removal in systems with constant loads.

-

Fixed Temperature Discharge Traps – Open at a preset temperature to protect equipment from freezing or overheating.

-

Inverted Bucket Traps – Rugged, long-life design suited for heavy-duty steam service with intermittent loads.

-

Sizes: NPT ½″ to 2″ – Flexible sizing for both commercial and industrial applications.

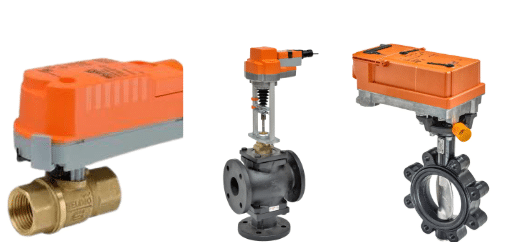

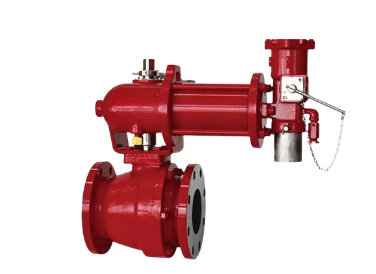

Modulating & Actuators

-

Specs: 120 VAC, -40°F to 140°F – Broad operating range to meet diverse control environments.

-

Electronic and Pneumatic Options – Compatible with modern building automation systems for responsive, accurate control.

-

Precise Flow Regulation – Ensures energy savings and consistent system performance in HVAC and steam networks.

Custom Designed Coils

-

Engineered to Specification – Designed and built to match unique system requirements in heating, cooling, steam and process applications.

-

Durable Construction – Built from high-quality materials to withstand demanding environments and extend service life.

-

Trusted Performance – Used in commercial and industrial settings where reliability and efficiency are critical.

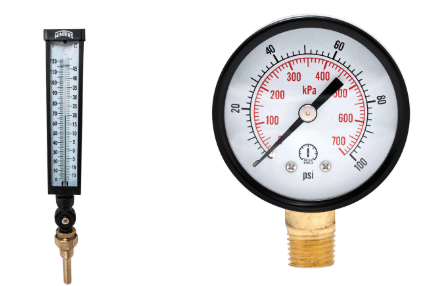

Thermometers & Gauges (Winters)

-

Precise Temperature & Pressure Monitoring – Engineered for accuracy, these gauges provide clear, dependable readings to ensure safe system operation.

-

Rugged, Long-Lasting Build – Manufactured to withstand harsh environments, with brass or stainless housings, shatter-resistant lenses, and industrial-grade performance.

-

High Ratings for Versatility – Suitable for applications up to 240°F and 300 PSI, making them a trusted choice across HVAC, hydronic, and steam systems.

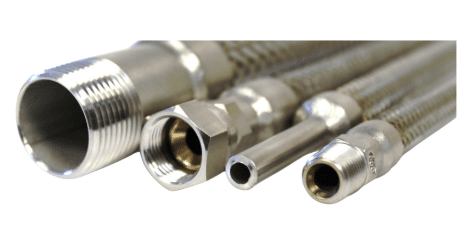

Flex Connectors

-

Absorbs Vibration & Reduces Noise – Stainless steel braided flex connectors minimize vibration from pumps, chillers, and piping, reducing operational noise and extending equipment life.

-

Compact, Flexible Pipe Protection – Ideal for tight mechanical spaces, their flexibility prevents misalignment stresses and makes installation faster and more reliable.

-

Corrosion-Resistant Construction – Built from high-quality stainless steel and elastomer materials designed to resist corrosion and scaling, ensuring long service life in hydronic and steam systems.

Pumps

-

Built for Demanding Durability – Pumps are designed for heavy-duty performance, handling everything from commercial HVAC to municipal systems with minimal downtime.

-

Efficient Hydronic Performance – Advanced hydraulics and ECM motors deliver energy savings of up to 80%, reducing operating costs while maintaining system balance.

-

Precision-Engineered Reliability – Backed by global leaders like Grundfos and Bell & Gossett, these pumps provide decades of proven performance with broad OEM and retrofit compatibility.

Flow Control Valves

-

Reliable Flow Regulation – Ensures accurate balancing of steam, water, and hydronic flow to protect equipment and optimize system efficiency.

-

Industrial-Grade Performance – Available in globe, ball, and butterfly designs with cast iron, bronze, or stainless construction to fit diverse applications.

-

Broad Compatibility – Designed for both new installations and retrofits, these valves integrate easily into HVAC, process, and steam systems for reliable operation.

Expansion Tanks

-

Carbon Steel Construction – Ranges from 11 to 104 gallons, built for durability under constant pressure cycling in hydronic systems.

-

ASME Section VIII, Div. 1 Certified – Code-stamped for safety and compliance in commercial and industrial applications.

-

Reliable Pressure Control – Designed for maximum operating conditions of 240°F and 125 PSI, these tanks protect boilers and piping from overpressure and thermal expansion damage.

Dampers

-

Precise Airflow Control – Automatically regulates draft in chimneys and venting systems to ensure safe, consistent combustion.

-

Energy-Efficient Actuation – Motorized and modulating dampers reduce standby losses, improving boiler and generator efficiency.

-

HVAC-Ready Performance – Compatible with a wide range of heating appliances, including boilers, furnaces, and water heaters, for improved system safety and efficiency.

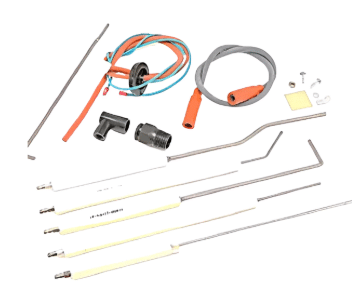

Annual Maintenance Kits

-

OEM Parts Simplified – Kits include original replacement gaskets, filters, seals, and other critical parts to keep equipment running to manufacturer specs.

-

Streamlined Routine Upkeep – Pre-packaged sets eliminate guesswork, making servicing faster and easier for technicians.

-

Minimizes Downtime – Ensures boilers and hydronic systems operate reliably year-round, preventing costly shutdowns.

Boiler Gauge Glass

-

Clear Fluid Level Display – Provides accurate water level monitoring, critical for safe boiler operation and ASME compliance.

-

High-Pressure Rated – Built to withstand demanding steam service environments, ensuring long-term durability and reliability.

-

Impact-Resistant Design – Toughened glass reduces the risk of breakage while maintaining visibility under harsh operating conditions.

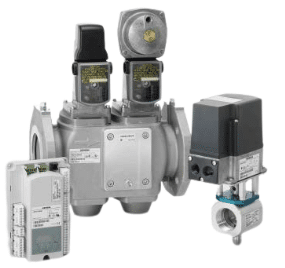

Combustion Control Systems

-

Flame Safeguards – Advanced monitoring ensures burners operate safely, with automatic shutdown features for fault conditions.

-

Burner Management Systems – Fully integrated controls handle sequencing, purge cycles, and efficiency optimization, reducing fuel costs.

-

Actuators & Gas Valves – Siemens precision-engineered components provide responsive, reliable modulation and combustion control for maximum performance.

Learn more

Please contact our team for more information on this product.